Issue Date: Nov. 4th, 2025

Memo Number: TB.MP.11425A

Revision: 1

Products Affected: All Handheld Laser Systems

Tools: #

- Masking Tape

- Nitrile Gloves

Instructions #

The following Instructions are intended to guide in the replacement of the protective cover slide (window) in all Theo handheld laser systems. These instructions will reduce contamination of the focusing lens and all other torch optical components.

Note: Establish a proper workspace of at least 1.5 meters around the unit. Make sure area is free of traffic and all lock-out tag-out procedures have been followed. Use proper PPE where needed.

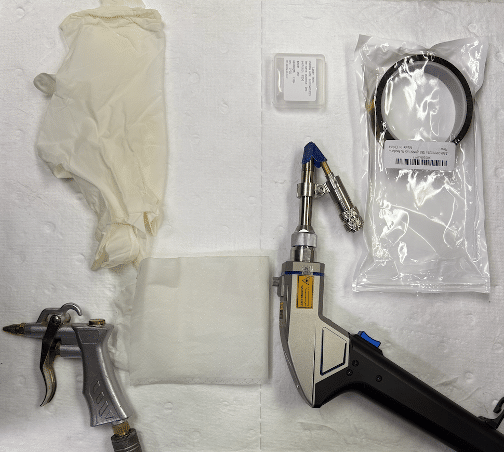

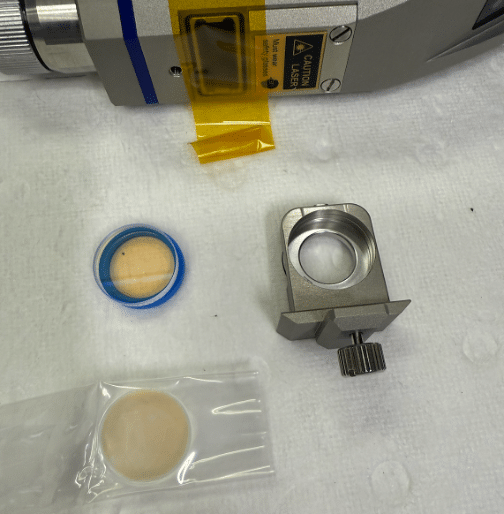

Gather all materials and tools needed to perform repair

- Low pressure air

- Power free gloves

- 70% IPA wipes

- Protective slide (Window)

- Kapton tape

- Masking tape (Painter’s tape)

Note the fiber bend radius at back of torch to ensure no less than 20cm

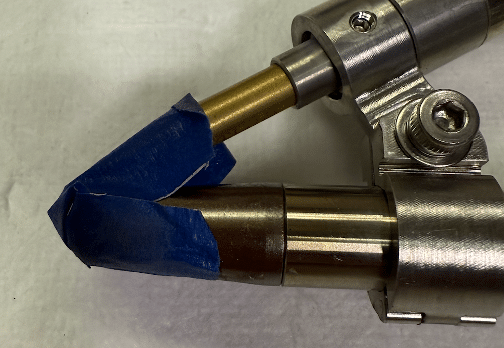

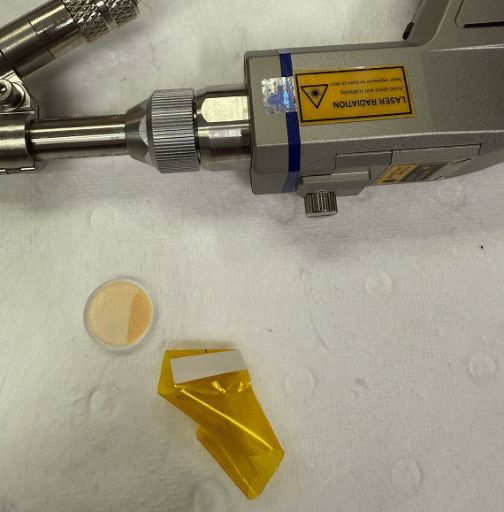

Seal torch tip with masking tape

Blow entire torch off with low pressure air to remove any loose particles

Wear dust mask while using compressed air

Put on gloves

Only use power free gloves when handling optics

Use IPA and particle free cloth to clean entire torch outer surface or 70% IPA cleanroom wipes

Set torch horizontally on flat surface

Never replace optics with torch cavity facing up

Do not run gas through the torch during optics replacement

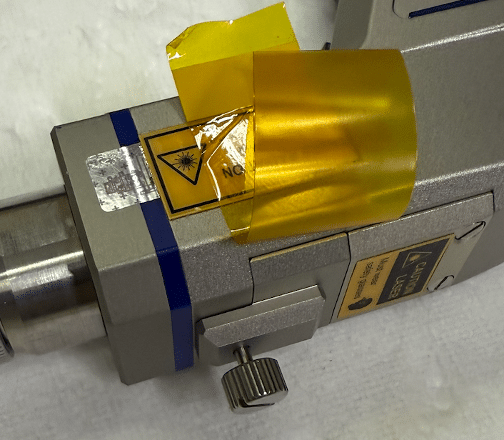

Cut a piece of Kapton tape long enough to cover the protective slide opening

Place tape above slide opening

Never use any other tape other than Kapton tape around optics

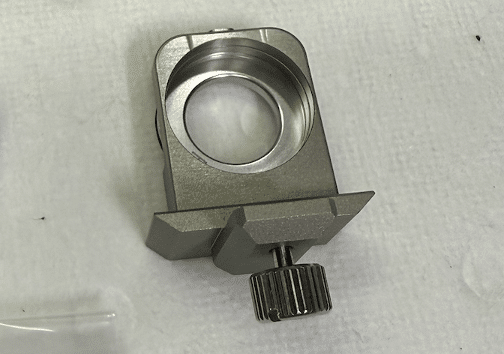

Unscrew the thumb screw for the protective slide counterclockwise

The screw is captive and does not need to be entirely removed

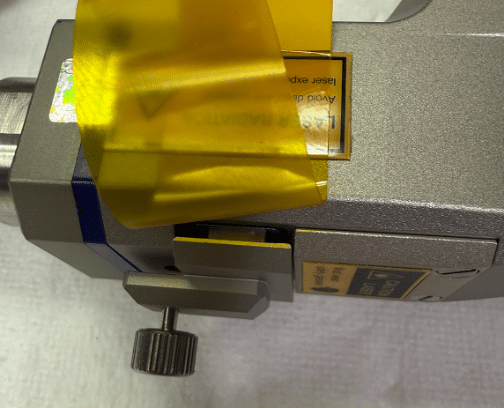

Carefully break seal, stop, and remove entire slide assembly by pulling outward

Do not pull quickly as this will draw a vacuum

Use your thumb of the hand supporting the torch to seal the open cavity with Kapton tape immediately after slide housing removal

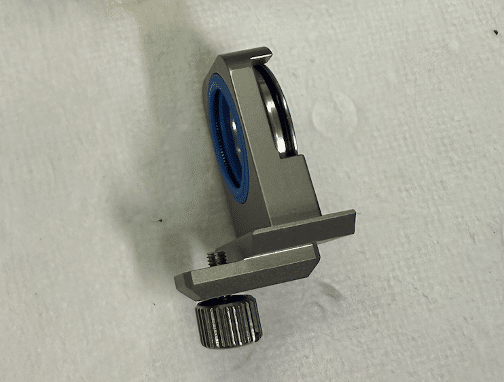

Push protective slide and sealing ring out of housing

Use low pressure air to clean particle from slide housing

Use IPA and particle free cloth to clean entire slide housing outer surface or 70% IPA cleanroom wipes

Install new slide with seal facing outward while the slide housing faces vertically as shown

Do not expose the slide to falling particles

Do not touch the face of the slide (even with gloves)

Never try to clean a protective slide

Always replace with new as the cost of the slide is not worth potential risks

Slowly remove Kapton tape to expose slide cavity

Reinstall slide assembly in torch

Screw the thumb screw clockwise to gently tighten

Do not over tighten

Clean work area and resume operation