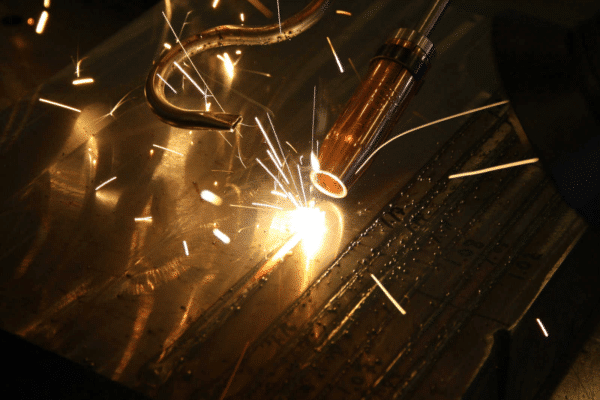

Safety comes first, not matter how efficient your laser welding is. In this article you’ll learn about the most common laser welding mistakes that can lead to risks. We’ll show you how to avoid them and weld safely. Precision means nothing without protection.

1. No Shortcuts on Personal Protection: Personal Protective Equipment (PPE)

A first safety red flag that is often overlooked is failing to consistently wear complete and certified Personal Protective Equipment (PPE). Even advanced systems like state-of-the-art lasers such as THEO, which are specifically designed with maximum safety in mind, cannot fully eliminate risks from reflections or secondary radiation.

Speed is good, but not at the expense of safety. Preventing potential injuries begins with strict adherence to PPE guidelines: always wear certified laser safety glasses that meet the European guidelines (EN 207 for full protection or EN 208 for laser adjustment tasks). Welding certified and laser approved PPE will make sure no skin remains exposed to harm.

2. Unsecured Work Area: Keep the Danger Zone Off-Limits

Another common safety oversight is an inadequately secured work area, often due to insufficient marking. This creates unnecessary risk, as unauthorized or unaware individuals may unknowingly enter zones while the laser is active.

Using laser safety enclosures, specifically designed rooms or laser safety curtains, marks clearly the laser work area. They’re safety highlight is their interlock connection to the handheld laser machine.

In addition, prominent laser warning signs at all entrances and a visible warning light signal to indicate when the laser is active, are essential precautionary steps. These measures help ensure safety so that only trained and authorized personnel have access to laser zones.

3. Reflective Surfaces: The Risk You Don’t See

Another frequently underestimated hazard involves superficial evaluation of reflective surfaces in the environment or the material being welded. This can result in unintended scattering or reflections of the laser beam. Even though THEO operates only on contact, nearby reflective surfaces can still pose a danger.

A thorough inspection of the work area to identify and remove reflective materials is essential to run safe operations. Make sure you always weld away from you. You should always stay behind the torch and keep a distance of around 500mm from the welding pool.

4. Safety System Maintenance: Trust Comes from Routine

Regular maintenance and functional checks of the laser’s built-in safety systems are non-negotiable. Neglecting these essential inspections increases the risk of undetected system failures that could endanger both personnel and equipment.

Routine maintenance following the manufacturer’s specifications is the foundation of safe operation. Prior to any workday, you should always verify the proper functioning of the workpiece contact sensor, emergency stop button, and all existing safety interlocks.

5. Missing Emergency Procedures: Training Turns Panic into Action

The fifth and last mistake of this short but essential checklist is a lack of clear procedures and inadequate training. This poses a significant threat, as it can hinder effective response in critical situations. Well-defined emergency procedures for laser-related accidents or malfunctions are key to warrant a quick and effective intervention.

Installing emergency stop buttons, marking first-aid equipment clearly, and making it easily accessible are also fundamental measures to address incidents quickly and reduce potential harm. To ensure all employees are to act safely and confidently in emergencies, regular training in first aid and specific emergency protocols should be a standard requirement.

To Sum it up

Safety is not an accident; it’s the result of knowledge and caution. Laser welding with Theo is about working faster, better – and smarter. But even the smartest tool needs a human who stays sharp. So: prepare, train, inspect. If you’re in doubt, check out our laser welding safety courses.