You’ve seen the speed, you’ve seen the clean beads, and now you’re ready to move. But jumping from traditional arc welding to laser technology isn’t just about swapping one torch for another. It’s a shift in how you handle safety, power, and workflow.

If you’re stuck at the starting line, here is exactly what you need to evaluate and prepare to make the transition.

1. Audit Your Material and Thickness

Laser welding is a specialist at thin-to-medium gauge work. Before you buy, look at your common projects. If you are primarily working with stainless steel, aluminium, or carbon steel between 0.5mm and 6mm, you’re in the sweet spot. While lasers can handle thicker materials with multiple passes or specialized settings, their primary strength is speed and low distortion on these gauges.

The Most Common Materials in Laser Welding:

- Stainless Steel. This is the most common application. It results in a silver, oxide-free weld that rarely requires post-process grinding.

- Carbon Steel. You can weld cold-rolled and hot-rolled steels easily. The small heat-affected zone reduces the risk of the part twisting or bowing.

- Aluminum (3000, 5000, and 6000 series). While aluminum dissipates heat quickly, the intensity of the laser overcomes this.

- Galvanized Steel. The laser can weld through the zinc coating, though proper ventilation is required due to fumes.

- Dissimilar Metal Joining. This is a major advantage. You can join copper to stainless steel or aluminum to steel. These combinations are usually difficult because the two metals have different melting points, but the laser’s precision creates a strong bond at the interface.

2. How Thick Can a Handheld Laser Welder Weld?

For laser welding systems, and especially handheld systems, thickness limits are dictated by the power source and the material type.

Penetration Limits by Power

When discussing penetration for handheld systems, the depth depends on the wattage of the laser source. The following values represent maximum penetration for a high-quality, single-pass weld.

| Material | 1.5 kW System | 2.0 kW System | 3.0 kW System |

| Stainless Steel | 4.0 mm | 5.0 mm | 8.0 mm |

| Carbon Steel | 4.0 mm | 5.0 mm | 8.0 mm |

| Aluminium (3000/5000/6000)* | 3.0 mm | 4.0 mm | 6.0 mm |

| Galvanized Steel | 3.0 mm | 4.0 mm | 5.0 mm |

| Dissimilar Metal Joining | 2.0 mm | 3.0 mm | 4.0 mm |

For thicker materials, a double-sided weld or a bevelled joint with filler wire is necessary.

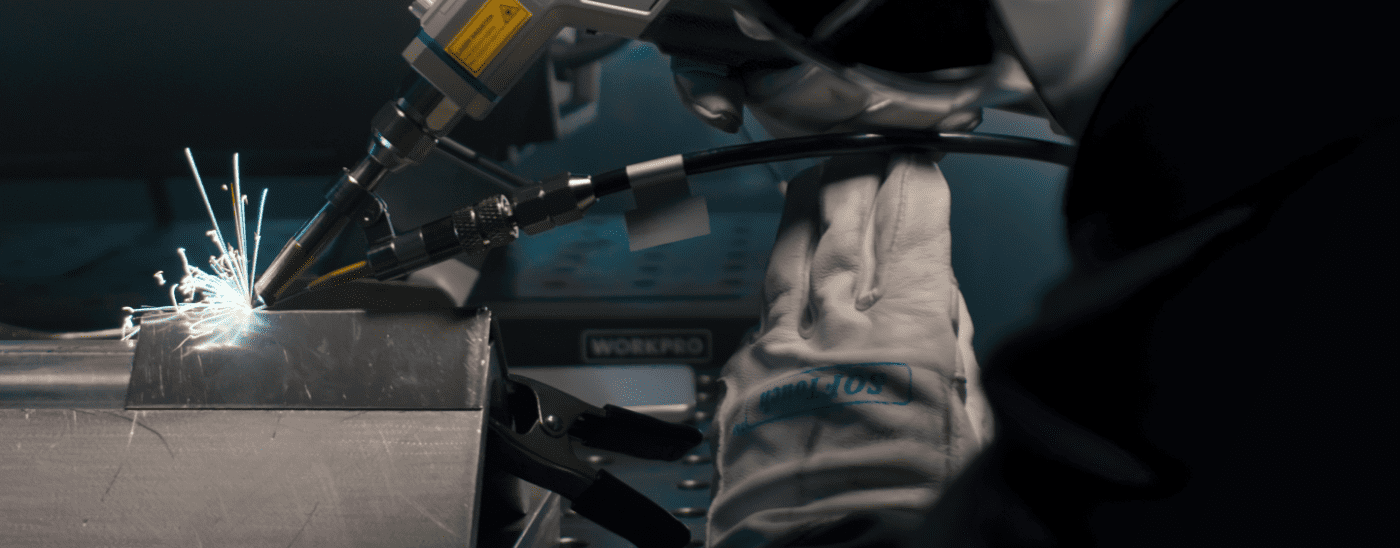

3. Laser Welding Safety Requirements: Create a “Class 4” Safety Zone

This is the biggest hurdle for most shops. Handheld laser welders are Class 4 lasers. The beam is invisible and the reflections can be just as dangerous as the direct hit. You cannot just fire this up in the middle of a busy floor with people walking by.

You need:

- laser welding safety enclosure. You need a designated area with laser-rated curtains or solid walls.

- Signage. Entry points must have interlock systems or at the very least, clear warning lights and signs.

- PPE. Forget your standard welding hood. You need specialized OD7+ rated glasses or a laser-specific helmet designed for the 1070nm wavelength.

Wear Laser Welding Safety Glasses or Helmets: Your Eyes Will Thank You

Specialized eye protection while operating a handheld laser isn’t optional; the light beam is invisible, but it can damage your sight faster than the human blink reflex can react.

If you think that standard arc welding helmets can keep your eyes safe, remember that they lack the necessary filtration for laser wavelengths. A direct hit or a stray reflection from a metallic surface are enough to cause permanent retinal burns or total blindness instantly. You should always use glasses or a helmet with the correct Optical Density (OD) rating for your specific equipment. This gear acts as a filter that blocks the hazardous light while letting you see the work.

4. Safety Power and Gas Infrastructure

The good news is that most handheld systems are remarkably efficient. What your set up needs:

- Electrical: Most professional units require a 220V/30A circuit. Check your breakers now so you aren’t surprised on delivery day.

- Shielding Gas: You’ll likely use Argon or Nitrogen. The setup is identical to your TIG rig—flow meters and tanks—but because you’re moving faster, you’ll often find you’re using less gas per inch of weld.

5. Laser Safety Class: Consider the Human Factor

You don’t need a four-year apprenticeship to use a laser, but you do need to unlearn some habits. There is no “dabbing” or “puddle manipulation” in the traditional sense. It’s about travel speed and maintaining the right “wobble” settings. Most experienced welders can get a feel for it in an hour, but you should appoint a Laser Safety Officer (LSO) in your shop to oversee protocols and ensure everyone stays safe.

Now You Only Have to Choose the Right Partner Sum it up

Once your shop is prepped, you need equipment that won’t quit. This is where THEO comes in. We built our units for the person who wants results, not a hobby. Our systems are designed to be “plug-and-play” with intuitive interfaces that remove the guesswork from your first day of operation. We don’t just sell the box; we provide the safety gear and the technical support to ensure your switch is a success, not a headache.

YOU MAY BE INTERESTED IN

TIME SAVER. THE MA1 SERIES

THEO MA1 Laser Welding Machine is a compact, easy-to-use, and highly efficient handheld laser welding system that offers superior return on invest compared to traditional welding methods.

THE ADVANTAGES OF LASER WELDING. IN YOUR HANDS

Laser welding offers a game-changing approach to joining metals, outperforming traditional methods like TIG and MIG welding in several key areas.

With laser welding, you can achieve up to 10x faster welding speeds, boosting productivity and profitability.